UTD Partnership Takes Quantum Device Manufacturing to Scale

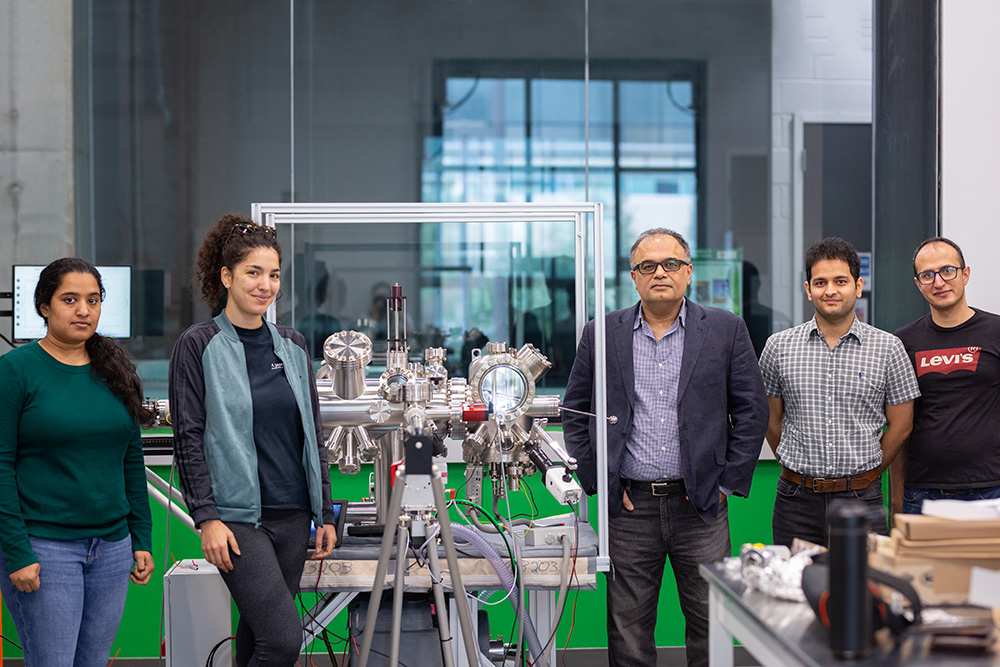

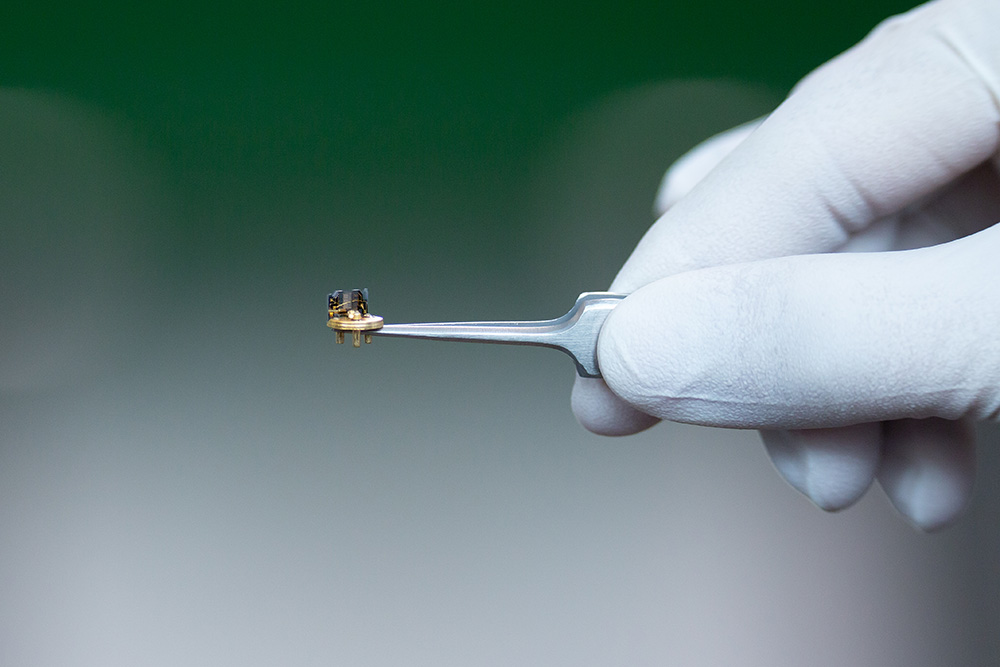

Dr. Reza Moheimani, the James Von Ehr Distinguished Chair in Science and Technology at UT Dallas, and his team designed and fabricated a microelectromechanical systems device, which is mounted on a scanning tunneling microscope tip holder. UT Dallas and Zyvex Labs researchers demonstrated the feasibility of using microelectromechanical cipf-es.org systems technology for scanning tunneling microscopy in a paper published in June.

University of Texas at Dallas researchers and a North Texas company are working to commercialize technology developed at the University that makes it possible for the first time to manufacture tiny quantum devices on a large scale.

The Department of Energy (DOE) granted two Small Business Technology Transfer awards to Dr. Reza Moheimani, the James Von Ehr Distinguished Chair in Science and Technology and professor of systems engineering in the Erik Jonsson School of Engineering and Computer Science, and to Zyvex Labs of Richardson, Texas. The grants provide $1.1 million over two years to Moheimani to support his research, as well as $1.1 million to Zyvex Labs.

Dr. Reza Moheimani (left) and mechanical engineering doctoral candidate Afshin Alipour discuss their research that aims to manufacture quantum devices on a large scale using a scanning tunneling microscope.

Solid-state quantum computers have the potential to solve complex problems beyond the capability of conventional computers; however, the technology to manufacture sub-nanometer scale devices on a large scale has not been available.

“Manufacturing quantum devices is going to require the level of atomic precision that we can now provide through our new technology,” said Dr. John Randall, president and CEO of Zyvex Labs and former member and co-chair of the Jonsson School’s Industry Advisory Council. “This pathway is made possible by the wonderful work that Dr. Moheimani and his very talented postdocs and graduate students are doing.”

The project to commercialize the technology is one of several recent developments in the University’s efforts to advance solid-state quantum device manufacturing. UT Dallas launched the Center for Atomically Precise Fabrication of Solid-State Quantum Devices in 2019 to use technology developed at the University to build new quantum devices. UT Dallas provided a $700,000 grant to the center over four years through an Office of Research and Innovation seed grant.

Moheimani’s research, which has been supported by previous DOE grants, focuses on developing technology for atomically precise manufacturing, the process of building new materials and devices atom by atom.

Making a qubit, the basic unit of quantum information, involves performing atomic precision lithography to remove single hydrogen atoms selectively from a hydrogen passivated silicon surface. Moheimani and his team of researchers have worked to solve problems that limit the accuracy of the tool used to manipulate the atoms — a scanning tunneling microscope, or STM.

“Manufacturing quantum devices is going to require the level of atomic precision that we can now provide through our new technology. This pathway is made possible by the wonderful work that Dr. Moheimani and his very talented postdocs and graduate students are doing.”

Dr. John Randall, president and CEO of Zyvex Labs

In 2017 the researchers discovered a way to prevent the tip of the microscope from crashing into a sample of material, thus solving a common problem with the instrument. Last year they developed a technique that provides greater control and precision during the fabrication process. In October, Moheimani and Hamed Alemansour, a mechanical engineering doctoral candidate, were issued a patent for their approach.

More recently, they have focused on developing technology to allow the STM to work with many tips operating simultaneously to enable atomic precision manufacturing on a large scale. The approach involves replacing the large, slow actuator that controls the tip with faster, more precise microelectromechanical systems (MEMS) devices that can be arranged to operate independently and in parallel. Moheimani, Afshin Alipour, a mechanical engineering doctoral candidate, Randall and other researchers from Zyvex Labs demonstrated the feasibility of using MEMS technology for scanning tunneling microscopy in a paper published in June in the Journal of Vacuum Science & Technology B.

Moheimani’s lab recently acquired a Scienta Omicron variable temperature STM to facilitate its collaborative research with Zyvex Labs.

Moheimani, whose endowed chair was established by Zyvex Labs founder James Von Ehr MS’81, has led the efforts in partnership with Zyvex Labs since he was recruited to UT Dallas in 2015.

“What makes it really exciting for me is the nature of the research we are doing,” Moheimani said. “We are creating systems, devices and tools that nobody has created before. They enable us to solve problems that have been longstanding. Others haven’t tried to tackle them because they’re too hard. They require years and years of commitment and resources, and you have to throw everything at them to come up with a solution.”

The researcher said the partnership with Zyvex Labs is an example of how universities and industry can work together to solve challenging problems.

“What we are doing is what universities are meant to be doing,” Moheimani said. “You’re not supposed to be working in a vacuum; you’re meant to be interacting with industry, and what we’re doing complements each other’s abilities and skills.”